Overview

The SentroPAT FO systems are a trusted cornerstone for Process Analytical Technology (PAT) in the continuous manufacturing of oral solid dosage pharmaceuticals. Renowned for their high performance, long-term stability, and seamless instrument-to-instrument transferability, these systems set the standard for reliability. Developed in close collaboration with leading pharmaceutical partners, SentroPAT FO is purpose-built to meet the rigorous technical and regulatory demands of the industry.

- Simultaneously measures the full NIR spectrum in milliseconds.

- Provides superior spectroscopic performance.

- Offers single-channel or up to 4-channel configurations.

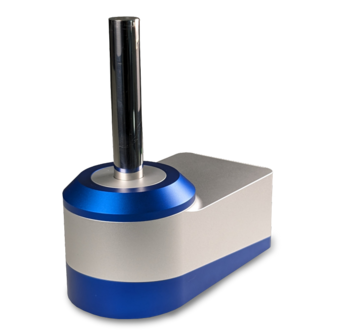

- Matches perfectly with SentroProbe diffuse reflectance probes.

- Ensures long-term stability with internal wavelength calibration.

- Seamlessly integrates with leading PAT management software.

Applications

While the capabilities of the SentroPAT system could benefit a wide range of industries, we have chosen to focus primarily on the pharmaceutical sector, particularly in the manufacturing of oral solid dosage forms. As a result, nine of the world's top ten pharmaceutical companies have chosen Sentronic as a trusted partner for their process analytical needs.

Technical Data

Need personal assistance? We’re here to help!

Looking for more tailored support? Don’t hesitate to reach out—we’re happy to assist you! Or explore our knowledge base for in-depth insights and technical details.

Frequent Asked Questions

Learn more about the SentroPat FO and its wide range of applications in pharmaceutical manufacturing. This section provides additional insights and detailed information to help you fully understand the potential and versatility of our cutting-edge sensor technology.

Yes, there are dedicated versions with 5W bulbs and SMA connector available to connect standard probes. Further the version for the SentroProbe DR MS 7 NIR has an integrated light source with a dedicated ferrule connector and 9W.

The measurements are made sequentially. Multiple input channels are switched to one spectrometer module by means of a mutliplexer with piezo based fiber movement.

For the SentroProbe MS7, the typical fiber optic cable length is 5.5 m. This probe uses a large fiber bundle, and fiber length has a significant impact on cost. However, when using the single-core 400 µm fiber required to connect a SentroProbe DR LS, cable lengths of 25 m or more are easily achievable.

System versions

SentroPAT FO is available in a couple of different version for either single-channel or multi-channel operation, with optional additional temperature control for demanding applications and optional internal light sources, e.g. for use with the SentroProbe MS7.

Additional Products

Explore our wide range of innovative products designed to meet the diverse needs of pharmaceutical manufacturing.