NIR PAT for High Shear Wet Granulation

The high shear wet granulation process is essential in pharmaceutical manufacturing, producing dense granules for controlled API release. It involves three key phases:

- Dry Mixing: Uniformly blending ingredients.

- Liquid Addition: Adding a binding solution.

- Massing/Granulation: Forming granules under high shear forces.

This process optimizes tablet properties such as hardness, dissolution, friability, flowability, and content uniformity, ensuring consistent quality in pharmaceutical production.

Why use NIR technology to monitor HSWG?

The high shear wet granulation process can be a vital unit operation in pharmaceutical manufacturing, producing dense granules for controlled API release and enabling the powder processing of poorly flowing materials or materials that may not compress well in a tablet press.

How can NIR support the process?

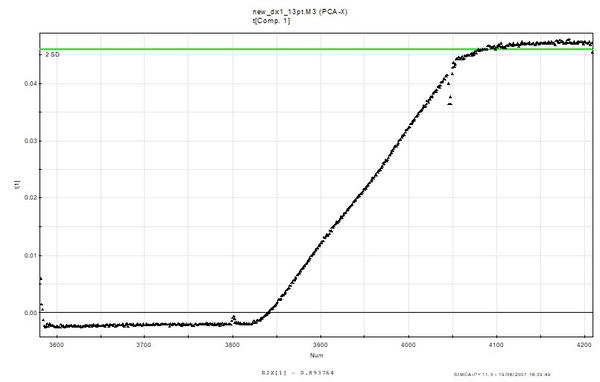

NIR PAT can provide tremendous process insight during formulation development, which can quickly and easily provide information on process end point and particle size distribution without arduous sampling or laboratory analysis. Data obtained during process development can be used to create models for end point detection or to optimize the process parameters in future development stages.

If NIR is consequently used during formulation development it can generate much data, which can be used to compare the process behaviour and results for the complete development process. This gained data can be used to create models for end point detection or to optimize the process parameters.

NIR can be used to support the transfer of a production process between different equipment and/or sites. Using the process data from the system in early development can be compared to the data generated on systems in later stages. Possible variations can be spectroscopically analyzed more easily to find the root causes for different process results.

When NIR data from small scale are available at the beginning of a process scale up, it can be used to compare with the data from the larger scale for an immediate check on the process. Combined process and NIR knowledge can efficiently support and speed up the overall process of scale up.

It is the goal to achieve process repeatability and consistent process results with reduced variability of the granulated mixture. The final goal is the development of an active process control to ensure the output quality of the granulation in a variation that is as small as possible.